External Wall Insulation Fixings

[draft]

If you have a cold house, one option is to put a layer of foam (and a little render to protect it) on the outside to keep it snug and warm inside.

Obviously, you’re gonna need some way to hold that foam on - you want it tight against the possibly uneven wall with no air gaps. People make long screws with plastic load spreaders for this purpose. Great!

But wait… if there is a long metal screw in there, surely that will be conducting the heat from the hot wall to the cold outdoors…

Well yes! I modelled it to find out how big the effect was:

Colours show the temperature. See the line across the image… Thats a metal screw in a plastic plug. They’re transferring about 0.012 watts/Kelvin/square meter out of your house, and a typical installation on an english house [400 square meters of wall, average temperature difference of 15C for half the year, gas heated, gas costs 10c/kwh], that will cost you £30/year.

Not too much, but over the lifetime of your house and all the other houses in the country, the cost (and the environmental damage) adds up to millions.

So… Is it fixable? Some use hammer-in plastic pins to affix the foam, but they tend to not hold the panels on firmly, allowing air to pass behind, with their own issues.

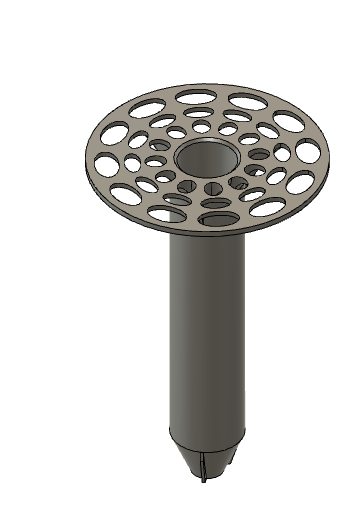

Another approach is to shorten the screw and change the design of the fixings. So I redesigned the fixings, cutting down the wasted energy by 94%.

In the new design, the screw is ‘sunk’ by about half of the insulation thickness, dramatically reducing energy loss.

Download the fixing design here to 3d print (in ABS, 100% infill), or contact me and I’ll send you a box of them.